The hunt for the perfect prototyping breakout boards ended at “Schmartboard” this time. At my first job, we had something we called “mini-mount” in the lab. Lots of them. And we used it to build all kinds of prototypes. Basically, it was a footprint for some SMT part on a thin single layer PCB with thin double-sided tape on the back. This was so convenient for quick mock-ups, prototypes, and when placed on a solid copper plane we could build very high-frequency stuff with this. And they were cheap.

I have been searching for these “mini-mount” things ever since. Not sure what the real name was and where they came from. I never really found anything quite as good.

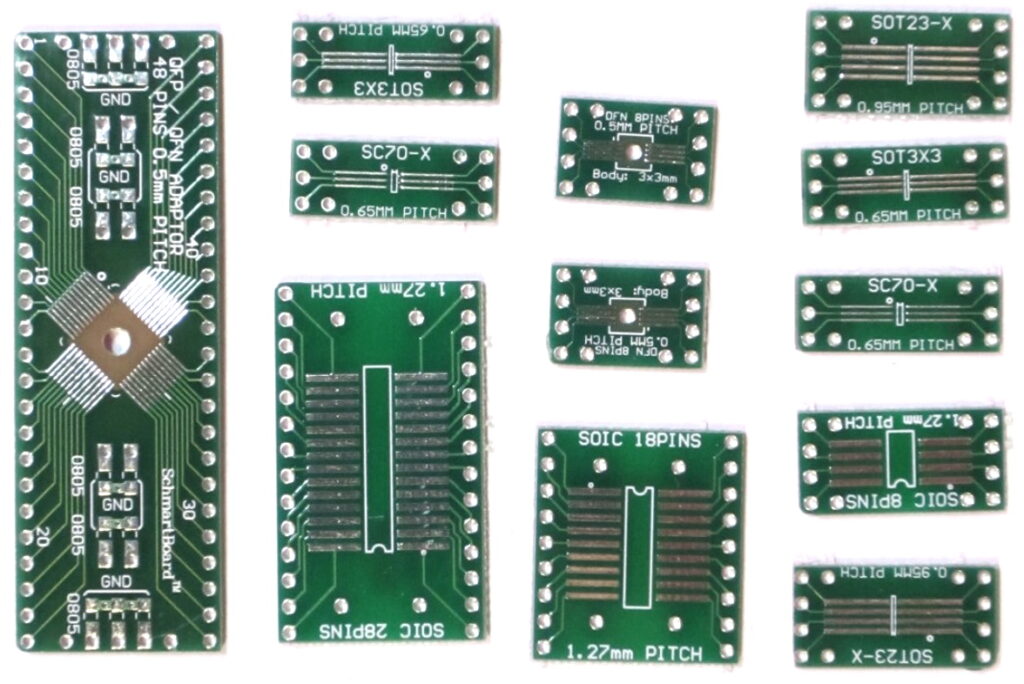

Recently the hunt was on again as I wanted to help my friend Matt build a super low power mock-up. So I discovered “Schmartboard”:

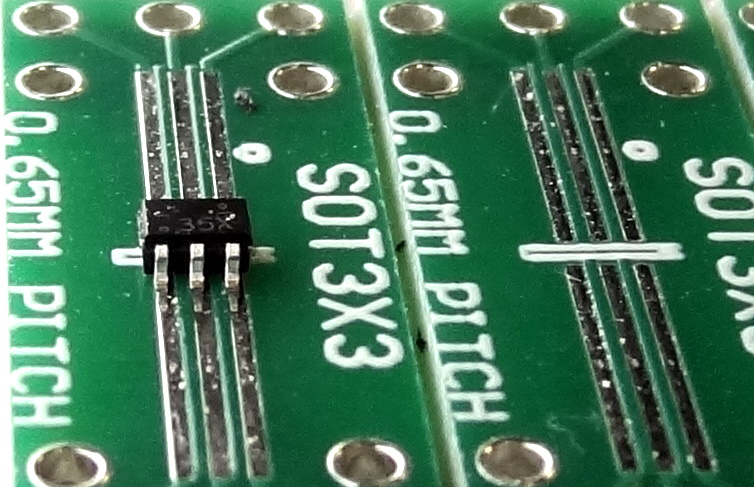

It’s not the same as our “mini-mount” back then. But it’s better in a way – and also worse. And it’s innovative. Let me start by explaining the innovation bit. By putting each (long) pad of the footprint into a groove, even the tiniest SMT parts align easily and can be soldered with ease. This is best shown in this photo:

It’s not the same as our “mini-mount” back then. But it’s better in a way – and also worse. And it’s innovative. Let me start by explaining the innovation bit. By putting each (long) pad of the footprint into a groove, even the tiniest SMT parts align easily and can be soldered with ease. This is best shown in this photo:

They even add the needed solder onto the trace in the groove so you apply flux and then “push” the solder towards the device and avoid adding too much solder. Hard to explain – try it (or see the video). This concept is pretty smart. I like it.

The good:

- Easy to solder

- Versions for all kinds of footprints

The bad:

- Not exactly cheap

- Shorts if placed on a copper plane (which I like to use as a common ground plane for SI reasons)

Hope you like it. Maybe not the end of my hunt for the perfect PCB breakout prototyping board, but Schmartboard does come close.

Let me know what you like to use?

PS: Read more of my random tips & tricks here.

M.Sc.EE, SI Consultant

M.Sc.EE, SI Consultant

Leave a Reply