Figuring out how to simulate ground bounce, Vcc bounce, SSN, SSO (or whatever you want to call it) is not trivial – this is a step-by-step guide to doing Hyperlynx SSN simulations right. This being so difficult is actually a shame, as it can very well be the most significant factor in your signal integrity analysis. This should be (and someday it will be) as easy as simulating reflections, crosstalk, etc.

But first let me explain what I mean by SSN (Simultaneous Switching Noise is also called Ground bounce or Vcc bounce), as there are different uses of the term. The basic premise is that we start with a very solid power distribution system (PDN), so there is a nice and sufficiently low impedance across the frequency range of interest. This is build up between two coupled planes in the board and this is where the IC connects through a set of vias (and maybe some BGA pad “dogbones”). Some want to include PDN effects in the SSN term, but I prefer to keep those terms separate.

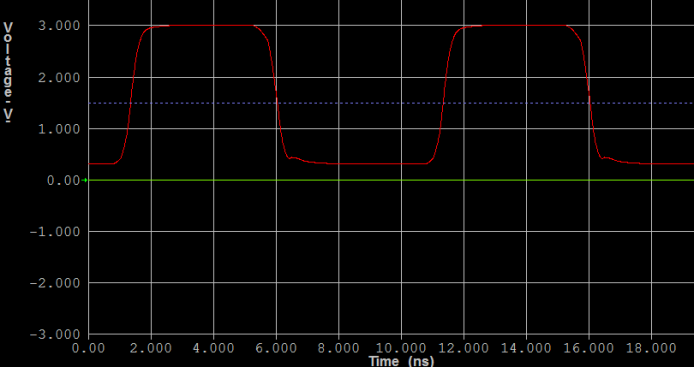

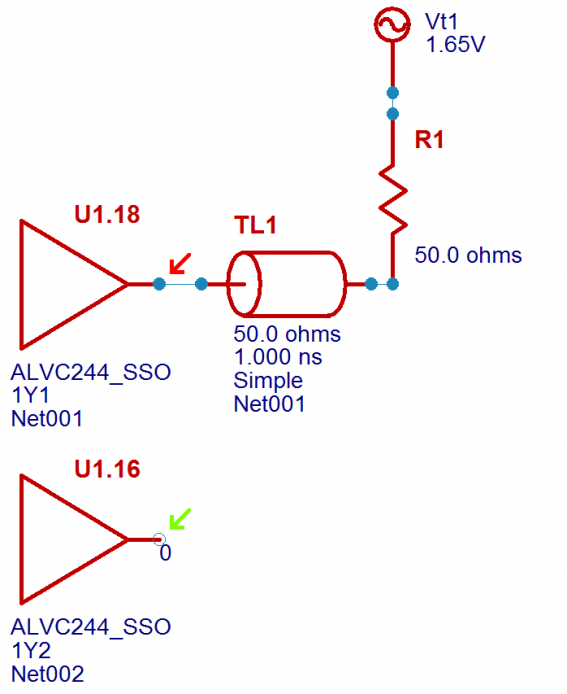

With this premise, the following simulation looks trivial (1.65V is half the 3.3V supply voltage):

The top output driver is clocked at some frequency – the lower one (U1.16) is set to “stuck low”. Now, what would you expect at the output of the lower one?

Unless you do some voodoo to the IBIS model file, all you will see for the lower output is a flat line at zero volts. Like this (red is the upper driver output; green is the lower output driver “stuck low”):

Why is this wrong? Well because of SSN.

The Vcc and Gnd connection between the IC pin and the die has some inductance – and across that inductance, we will have a voltage whenever the current changes. This follows the simple formula: U = L * di/dt.

Whenever the output of the top driver output changes, some current will flow through the shared Vcc or Gnd connection of the IC. For the high-to-low edge of the U1.18 output, this current will run through the ground bond wire and IC pin and create a voltage difference between the ground pad on the die and the ground plane in the PCB. This is what I call ground bounce or SSN. Same but opposite for Vcc bounce.

If we think of the simulators ground or 0V point as connected to the ground plane in the PCB, the “stuck-low” output of U1.16 should then show something different than a flat line at zero. Doing Hyperlynx SSN simulations is not that simple.

How do we get Hyperlynx to do so? Well, this requires some modifications to the IBIS file. Here are the steps:

Identify the Power Pins

This is a very simple IC (on purpose to keep confusion to a minimum) with only one power and one ground pin. So open the IBIS model file (which is just a plain text file) in a suitable editor and locate the pin section for the package of interest.

[Pin] signal_name model_name R_pin L_pin C_pin | 1 1NOE ALVC244_IN 4.200e-02 6.336e-09 8.650e-13 2 1A1 ALVC244_IN 4.300e-02 5.542e-09 8.670e-13 3 2Y4 ALVC244_OUT 3.400e-02 4.714e-09 7.320e-13 4 1A2 ALVC244_IN 3.400e-02 4.377e-09 5.910e-13 5 2Y3 ALVC244_OUT 3.600e-02 4.130e-09 5.330e-13 6 1A3 ALVC244_IN 3.500e-02 4.111e-09 5.300e-13 7 2Y2 ALVC244_OUT 3.400e-02 4.284e-09 5.830e-13 8 1A4 ALVC244_IN 3.400e-02 4.634e-09 7.260e-13 9 2Y1 ALVC244_OUT 4.000e-02 5.518e-09 8.650e-13 10 GND NC 4.300e-02 6.349e-09 8.660e-13 11 2A1 ALVC244_IN 4.100e-02 6.281e-09 8.610e-13 12 1Y4 ALVC244_OUT 4.500e-02 5.561e-09 8.680e-13 13 2A2 ALVC244_IN 3.300e-02 4.778e-09 7.420e-13 14 1Y3 ALVC244_OUT 3.500e-02 4.414e-09 5.960e-13 15 2A3 ALVC244_IN 3.500e-02 4.110e-09 5.330e-13 16 1Y2 ALVC244_OUT 3.600e-02 4.130e-09 5.330e-13 17 2A4 ALVC244_IN 3.400e-02 4.377e-09 5.910e-13 18 1Y1 ALVC244_OUT 3.400e-02 4.714e-09 7.310e-13 19 2NOE ALVC244_IN 4.300e-02 5.569e-09 8.680e-13 20 VCC NC 4.200e-02 6.308e-09 8.640e-13

Two things are important here:

- Find the parasitic package induction: 6.35nH for Gnd and 6.31nH for Vcc in this case. You can also find the DC resistance and the parasitic capacitance.

- Make sure the 3rd column reads NC for the Vcc and Gnd pins.

You may want to change the name of the IBIS file when you save it – but remember to change the file name reference in the file as well when you do that.

Create a Spice Sub-Circuit

Now create a plain text file with the Spice simulation lines to define these parasitic elements. Here we place it in a file called “pwrSupply.inc” like this:

* Power supply circuit with package parasitics for pins 10, 20 .subckt pwrSupply_3v3_with_parasitics pwrref gndref Vgnd p10 0 DC=0 Vpwr p20 0 DC=3.3 C_p10_pkg p10 0 C=8.6600000e-013 L_p10_pkg p10 p10_RL L=6.3490000e-009 R_p10_pkg p10_RL gndref R=4.3000000e-002 C_p20_pkg p20 0 C=8.6400000e-013 L_p20_pkg p20 p20_RL L=6.3080000e-009 R_p20_pkg p20_RL pwrref R=4.2000000e-002 .ends

This simple Spice circuit describes the two power pins and their associated bond wires – basically everything from pin to die. You can see it’s a crude description, but enough for many purposes – and this is all the information most IBIS files have. Lumped element R/L/C models for each pin.

Put Circuit Call in the IBIS file

Back in the IBIS file, you need to call this Spice sub-circuit and define which outputs are connected to these power rails. To simplify things, we only define this for the two outputs on pin 16 and pin 18:

[Node Declarations] pu_ref pd_ref [End Node Declarations] | [Circuit Call] pwrSupply Port_map Vcc_pad pu_ref Port_map Vss_pad pd_ref [End Circuit Call] | [Circuit Call] ALVC244_OUT Signal_pin 16 Port_map A_signal 16 Port_map A_puref pu_ref Port_map A_pdref pd_ref Port_map A_pcref pu_ref Port_map A_gcref pd_ref Port_map A_gnd pd_ref [End Circuit Call] | [Circuit Call] ALVC244_OUT Signal_pin 18 Port_map A_signal 18 Port_map A_puref pu_ref Port_map A_pdref pd_ref Port_map A_pcref pu_ref Port_map A_gcref pd_ref Port_map A_gnd pd_ref [End Circuit Call]

You can place this right after the pin assignments in the IBIS file. All it does is really connect the power rails of the two I/O cells for pin 16 and 18 to the two new nodes called pu_ref and pd_ref – and connect those two nodes to the Spice sub-circuit.

Define the Spice Circuit Ports

As the last step we can add the definition and parameter mapping of the new Spice sub-circuit file like this:

[External Circuit] pwrSupply Language SPICE Corner typ pwrSupply.inc pwrSupply_3v3_with_parasitics Ports Vcc_pad Vss_pad [End External Circuit]

That’s all. We are now ready to simulate the original simple schematic with the full SSN or Ground/Vcc-bounce effect.

Simulation Results

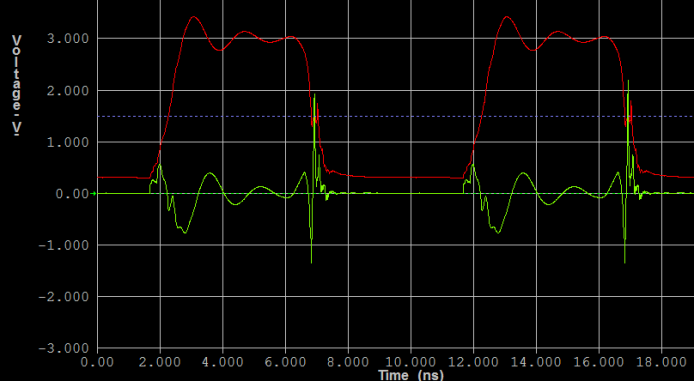

This is how the simulation of the same circuit looks now:

Notice the difference in the green curve (the “stuck low” output)?

And the red curve is impacted quite a bit as well… Almost to the point where you question the validity of the simulation. And you should. So the next step is to scrutinize the simulation setup – and verify it with measurements.

Capacitance

One of the things that can make this Hyperlynx SSN simulation come out as if the part is completely useless because of excessive SSN is the complete lack of die and package capacitance between power and ground. It is very difficult to imagine the die not having at least some capacitance between power and ground.

The good thing about simulators is that experiments are easy to do and free. Let’s try to add 10pF between power and ground at the die and see what happens. To do this, add this line to the Spice file:

R_p20_pkg p20_RL pwrref R=4.2000000e-002

C_die gndref pwrref C=10e-12

.ends

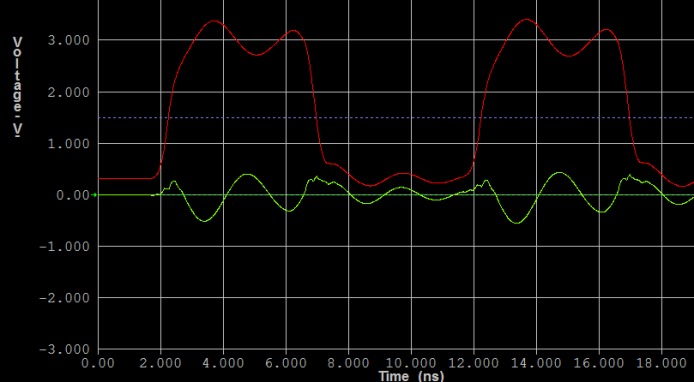

Now run the simulation again to see how much of an effect this has:

Quite a dramatic effect. This shows how important on-die and on-package capacitance really is. And it also highlights how bad IBIS models are in predicting SSN at the current stage.

How do you think it would look, if someone actually hooked this up on a board and did some measurements? Comment below.

Disclaimer: This is written for Hyperlynx 9.1 – expect SSN simulations to get easier as tools and models evolve. This method is only useful for Hyperlynx – other IBIS simulators have different ways of doing this.

M.Sc.EE, SI Consultant

M.Sc.EE, SI Consultant

Leave a Reply